Technical Reference

Heavy Duty Ball Transfer Units – Maximum Precision

|

Finishes”Anti-oxide” electrophoretic black finish >330 hours ISO salt resistance. Stainless steel units – natural finish |

|

Felt SealFelt Seal as standard (Ball Ø > 1/2″ ) |

|

OilLubricated for life – Mobil Vactra 1 Oil |

|

18000 lbsLoad ratings unaffected at any orientation |

Load & Stability

|

Ensure sufficient load capacity. Load 3 = 3 x 1000Kg |

|

Standard A 1 x drain channel |

Debris & Drain Channels All units (main ball) >15.8mm |

Z 2 x drain channel |

Component materials & Corrosion resistance

| SS | All parts Stainless Steel | 1 | 1 | 1 | 5 | 3 | 3 |

| Z | Arduous Conditions | 4 | 4 | 1 | 5 | 3 | 3 |

| A | Stainless steel balls, other materials as standard | 4 | 4 | 6 | 5 | 3 | 6 |

| Standard Materials | 4 | 4 | 6 | 5 | 6 | 6 | |

|

1 = AISI 304 stainless steel |

| 2 = AISI 302 stainless steel | |

| 3 = AISI 440 stainless steel | |

| 4 = AISI 1050 Anti-oxide finish | |

| 5 = AISI 1070 chrome steel | |

| 6 = AISI 52100 chrome steel |

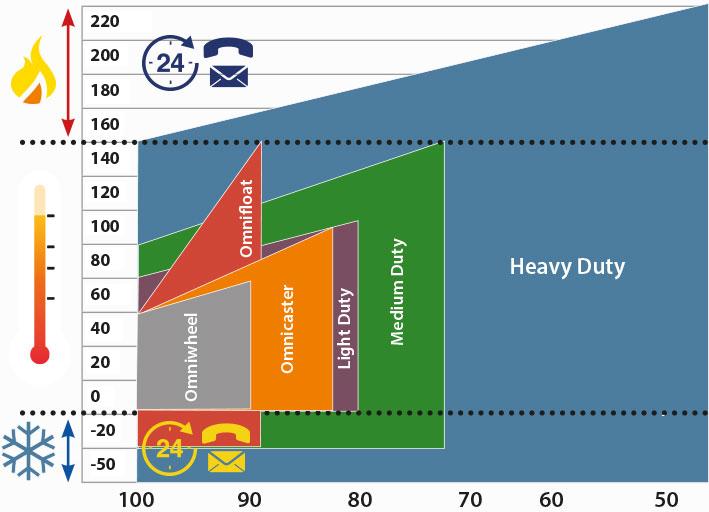

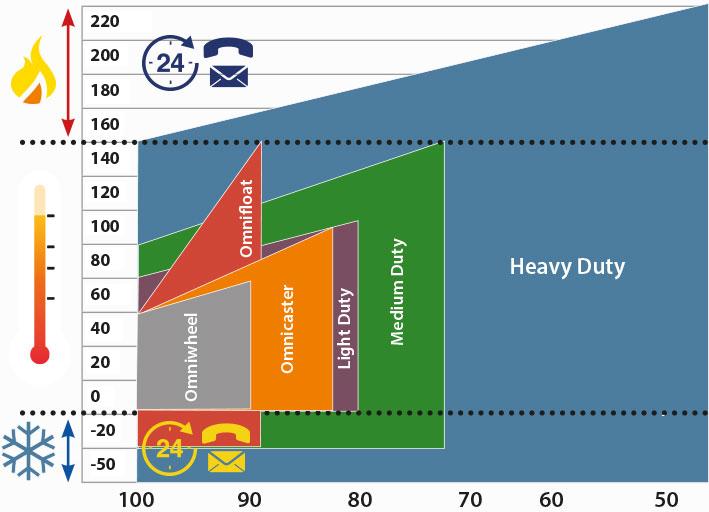

Operating Temperature

Evaluate these aspects when choosing your own solution:

Orientation

Which positions does your application require the units to be mounted or function? Load ball ‘up’, ‘down’, or other? Heavy duty range units operate ay maximum load in all orientations.

Track & Contact

What is the condition, hardness & surface finish of the material the units will be be conveying or bearing against? Uneven, deformable & delicate surfaces need special consideration.

Load

Dynamic & static load ratings are identical. Where loads are unevenly distributed or high impact/shock conditions exist, spring loaded units are ideal.

Speed

Maximum conveying speeds are limited frequency & duration may also require consideration. Dynamic & static speed ratings are identical.

Friction & Precision

Lowest coefficient of friction & highest levels of precision movement are provided by the Heavy duty range units. Some applications will allow a design concession to be made.

Stability

Consider the stability of the conveyed item. Ensure sufficient points of contact (pitch) to consistently support the mass. Provision for control & braking of the mass should not be overlooked.

Environment

Consider material upgrade options to better resist adverse environmental operating conditions: dirty or dusty conditions? Wet & contaminated areas? Chemical attack/contamination? Magnetic permeability & Radioactive fields.

Lubrication & Service

Omnitrack products are lubricated for life. Heavy duty & Omnifloat ranges offer additional user-service kits to further extend service life.

Temperature

Ambient temperature & maximum/minimum temperature ranges must be evaluated. Stainless steel components resist higher & lower temperatures better than standard materials.